Sanding abrasives work by removing material with thousands of small abrasive particles embedded in the paper or pad. Starting with a coarse grit helps to quickly eliminate surface imperfections, and then gradually moving to finer grits refines the finish. Each finer grit erases the scratch marks left by the coarser grit used before, resulting in a smooth, even surface.

Types of Sanding Abrasives and Their Uses

Sanding abrasives are available in various formats, from sandpaper sheets to sanding discs, each designed for specific applications. Higher-quality abrasives are generally more durable and effective, lasting longer and offering consistent performance.

Here’s a breakdown of different grit levels and their purposes:

- Coarse Grit (40-60): Ideal for heavy-duty sanding, removing significant imperfections, scratches, paint, or rust.

- Medium Grit (80-120): Suitable for general sanding and preparing surfaces for finishing.

- Fine Grit (200+): Used for final finishing and polishing to achieve a smooth, polished look.

Sandpaper grit ranges from very coarse (40 grit) to very fine (400 grit), allowing for precise control over the sanding process and ensuring an optimal finish for any project.

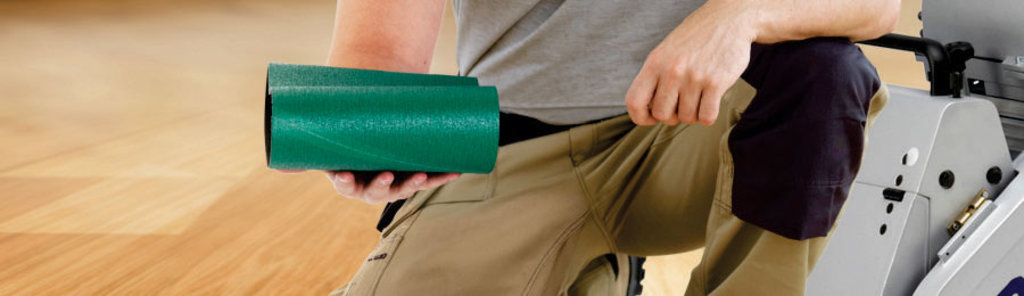

Sanding is not only useful but it also makes the whole difference for your wooden floor, improving its condition, minimising the risks of issues, ensuring protection, and improving the appearance. However, for sanding to happen, you need sanding abrasives. Sanding abrasives is a category that summarises all different accessories and tools that utilize the abrasive function of sandpaper, including the most popular sanding abrasives used for wood floor sanding – disks and sanding belts. In this context, sanding abrasives are flooring accessories used together with sanding machines and technology for stripping down the top layer of every hardwood or engineered wood floor. By removing this top layer, sanding abrasives are removing the old finish and all the small imperfections on the surface of the floor. Sanding abrasives are improving the condition of the floor by minimizing the risk of such imperfections grow bigger and cause serious issues.

Sanding Abrasives – Grit

What Does Sanding Abrasives Grit Mean?

Sanding abrasives and sandpaper come with different grits and different grits of sanding abrasives are used for every wood floor sanding project to achieve a perfectly smooth and even surface with no imperfections and no trace of the old and worn finish. The grit of sanding abrasives is the rating of the size of abrasive materials on the sandpaper or the intensity of the sanding abrasives to say otherwise. The higher grit number of sanding abrasives is the equivalent of finer abrasives. Such sanding abrasives are usually used for the final touches of every wood floor sanding project, creating a very smooth and uniform surface, or sometimes for buffing projects when the surface of the floor is treated lightly. Lower numbers of sanding abrasives grit are coarser abrasives and used for scraping off the old finish of the floor, scratches, dents, marks, gouges, dirt build-ups, and more.

Sanding Abrasives – Different Materials

What Are Sanding Abrasives Made From?

Sanding abrasives are made from different materials that vary chemically. Some sanding abrasives are made from grains of the natural material garnet, while there are also some made from synthetic materials such as aluminium oxide, alumina-zirconia, and silicon carbide. No matter what type of material is used for the creation of the sandpaper, the most important thing that determines its quality and efficiency is whether the bond between the abrasive part and the backing material is strong enough.

How to Shop for Sanding Abrasives?

Understanding Sanding Abrasives

The size of the grit of every piece of sandpaper is measured via the Coated Abrasives Manufacturing Institute and the Federation of European Producers of Abrasives. In general, there are two main subdivisions of sanding abrasives – micro and micro. Both categories include many more gradations.

Sanding abrasives – grit Sanding abrasives – different materials How to shop for sanding abrasives?